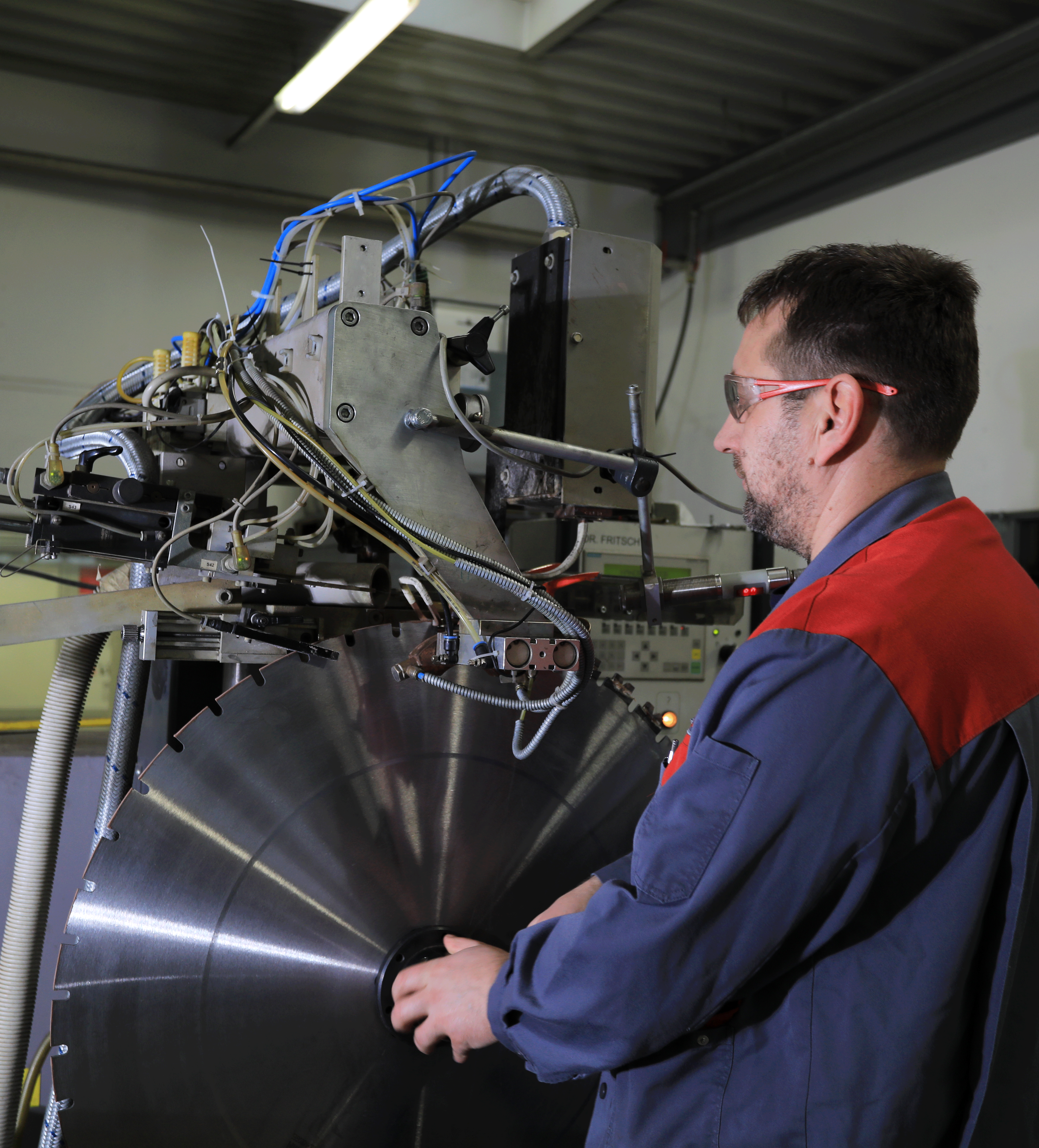

Retipping wall saw blades is possible for all diameters. Especially for large diameters, starting from 1,400 mm, it is economically reasonable. After retipping, the saw blade is straightened to achieve the required positive or negative tension in the master core.

It is possible to repair wall saw blades with lost segments. For this purpose, new segments are brazed to the blade, the saw blade is tensioned appropriately, and it is straightened.

For the retipping process, there are different segment types available, the process used depends on the corresponding application area.

Wall saw blades with a master core below 2.8 mm thickness are no longer usable.

Retipping process:

/ After receiving the wall saw blade, its quality is assessed

/ If the required criteria are not met, the further procedure is discussed with the customer

/ Cleaning the wall saw blade

/ Removing old segments, grinding the blade circular and cleaning the fillets

/ Saw blade is retipped – brazed

/ Straightening and tensioning the blade

/ Sharpening all segments

/ Application of corrosion protection onto all segments and bonds